Power tools are expensive and if you happen to find one that’s relatively cheap well, good luck with that because it probably won’t last as long as you expect. Even more recently, inflation is up, which happens to affect the prices of everything, which is an unfortunate tabulation we’re forced to include.

Currency troubles aside, quality or premium power tools are expensive for a wide variety of reasons, all of which we will touch on here, along with the best ways to find deals on power tools and how to separate the wheat from the chafe.

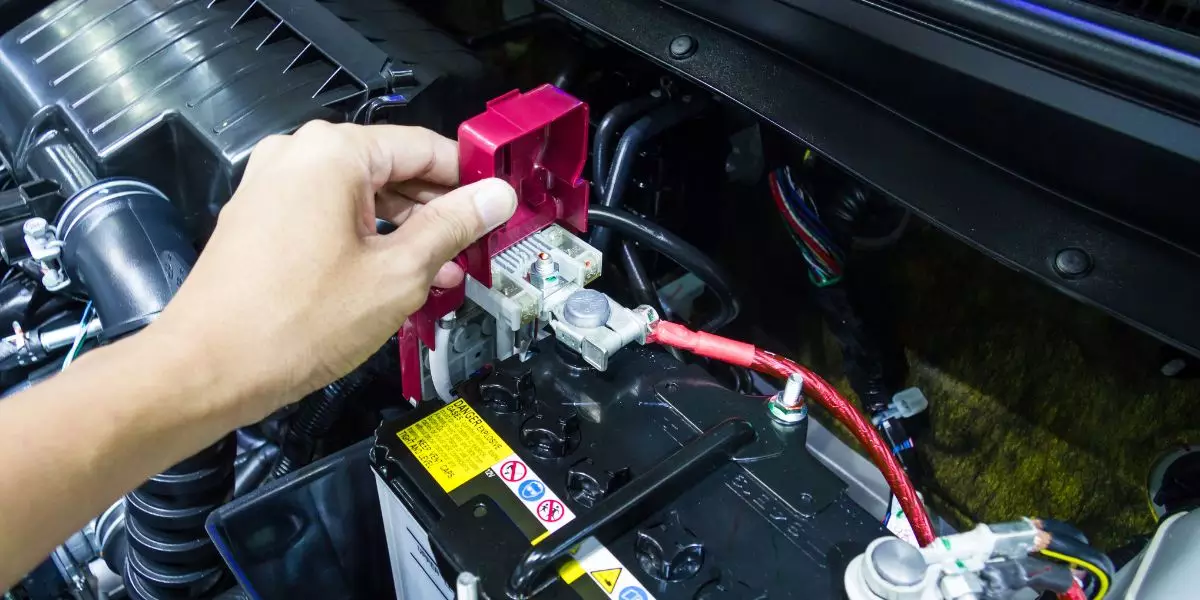

Inductive Charging Lithium-Ion Batteries

The lithium-ion battery market is exploding upward, with lithium-ion finding its way into just about every major device on the market. You can find lithium-ion batteries in marine batteries, leisure batteries, cell phones, smartwatches, drones, tablets, vehicles, generators, and more.

It’s a welcome addition to the battery-powered side of our world, especially considering the facts: lithium-ion batteries are very lightweight, easier to charge, hold more charge for longer periods of time, and more efficiently release that charge, so your devices last longer.

Since it isn’t full of liquid, like AGM or lead-acid batteries, it’s easier to install and use, and they aren’t as likely to explode when agitated. Because its a highly reactive element, it is simply the far superior choice for holding and dissipating charges at much higher levels.

When it comes to rechargeable lithium-ion batteries—which essentially make up the entire lineup of cordless power tools—they are able to maintain a superior level for far more charge cycles than standard batteries.

Because of this same technology, lithium batteries have a very low natural discharge rate. Natural discharge is the slow and inevitable discharge from batteries that are just sitting on standby, crammed in a drawer, or left in the packaging.

Their low maintenance requirements and the fact that they are eco-friendly also place them on the higher tiers when it comes to price points.

As you can see, there are a ton of benefits to lithium-ion batteries and with the addition of inductive charging—a form of wireless energy transference—power tools are only getting more expensive by the day.

Fortunately, there is a light at the end of the tunnel. As with all new technologies, prices begin in the stratosphere. Take TV resolutions for example. When 4K TVs were first released, the prices were staggering, making them available only to the wealthy.

Now, you can purchase a 4K smart TV, with a very large screen, below $500 easily. The same thing will happen with lithium-ion batteries over time.

Brushless Motors

Newer technologies require better batteries to operate and brushless motors are no exception. Old school batteries aren’t as efficient running newer tech, so they are more likely to be less cost-effective as the technology that they’re required to power evolves. The same goes for power tool prices.

Speaking of new technologies, it would be dishonest to say that the newness of brushless motors is responsible for driving up power tool prices. However, the brushless motor has been around since the 1800s, so that argument withers on the vine as soon as it’s exposed.

In this case, it’s more a matter of being newly introduced rather than being a new tech. Although brushless motor technology and understanding have been around for a long time, it’s never a technology that has been widely used in anything, especially not in power tools.

Now brushless motors are becoming extremely popular in a wide variety of applications, including power tools. Since brushless motors are not a new technology and aside from the fact that it is a new application, why does it drive up the price of power tools?

- Reversed magnets and windings

- Small circuit board included

- Power is based on usage

- No friction and voltage drop

- Higher efficiency and longevity

- Cost barriers for manufacturers

The reversed magnet and windings are a more efficient method in motor technology, creating less force with more spin. All brushless motors also require the addition of a small circuit board, which will obviously drive up prices.

Because of the circuit board, the power tool can tell the difference in resistance. For instance, drilling into plastic will require a certain amount of energy, which is pretty low. Switching from plastic to oak, however, will require more energy, so the circuit board adjusts the level of power required.

Since there is no friction—there aren’t any brushes encountering resistance as they spin against the spinning commutator—you won’t experience any voltage drop. A brushless motor is free to spin and doesn’t have to deal with friction in any form.

Because of this, brushless motors are far more efficient and durable. Any sort of friction causes a slow and steady degradation of the material. Since the brushless motor doesn’t have to deal with friction, it will last longer.

Cost barriers are a significant factor for manufacturers, because of the chip technology, superior metals, and design accommodations necessary to manufacture a superior machine with a brushless motor.

Unfortunately, that means that the excessive costs of manufacturing both the brushless motor power tools and the higher-end batteries to supply them with power are passed on to the consumer, which is you.

Batteries Are Sold Separately

One of the more mystifying marketing, production, and distribution factors that makes shopping for power tools especially frustrating and difficult is the fact that often, the entire power tool doesn’t come together.

For instance, you can purchase a particular power tool—let’s say a cordless sander—and the sander comes as a standalone device. Now, you have to buy a rechargeable battery, which costs as much as the tool. Once you’ve acquired the battery, you have to have a charger for it.

On and on it goes. For whatever reason, power tools often sell all of these things separately, rather than in a complete package. Ordering online will often counter this, as you can purchase power tools in packages, including everything that goes with them, for a reduced price.

Why so many power tools are sold this way is an interesting question. To make things even more difficult, power tool batteries are not exactly standardized. You may end up buying a battery that visually matches the pins on your power tool only to discover that it won’t adequately charge it.

It basically boils down to the fact that the manufacturer knows you need the battery and, irritatingly enough, “batteries not included” is suspiciously missing from the box or the fact that the power tool doesn’t come with one is in tiny print on a tiny corner, mashed in amongst a lot of text.

Since you need the battery, it’s more than easy to just sell it separately, in its own package, for an exorbitant price. After all, without the battery and/or the charger, what use is your power tool?

Number of Cycles

This was briefly touched on with the lithium-ion batteries. Since lithium-ion isn’t the only type of power tool battery out there, it’s worth mentioning the reasoning behind the cost of power tool batteries.

One of the major improvements in power tool batteries over the years is the number of cycles you get through recharges. With nickel-cadmium batteries, you may get roughly two hours of use before the battery needs recharging.

With lithium-ion—depending on the level of usage—can extend that usage time to up to 4 hours before it needs to be recharged. However, it’s not the fact that they can’t take a charge so much as how many cycles (or recharges) they can handle before the battery essentially becomes a paperweight.

The standard that most manufacturers try to meet requires their batteries to accept at least 1,000 cycles of use and recharge before they are no longer viable. With the introduction of lithium-ion batteries that can withstand 1,000 cycles, other batteries have to increase their production to match.

In other words, the addition of lithium-ion has effectively driven up the price of NICAD (Nickel Cadmium) batteries. In order to match their new standards, the production of NICAD batteries necessitates appropriate modifications and improvements so NICAD batteries can compete.

Lithium-ion batteries are expensive and they’ve driven up the price of NICAD batteries. However, although NICAD batteries can meet the Lithium-ion standard of 1,000 cycles, the NICAD batteries have to be recharged at a much higher rate.

If you own a NICAD battery, you’ll get your 1,000 cycles, however, you will burn through that battery at a minimum of 2X faster than a lithium-ion.

Battery Longevity Drives Up the Price

In the race to make the longest-lasting battery on the market, manufacturers are innovating and new innovations in the battery market mean higher prices. Not only that but the standard, 20v, lithium-ion battery is expected to last three years.

Selling a battery that lasts three years means you have to make your money now because, if your product works as advertised—and no business wants to get caught up in false advertising—then you either need to sell more power tools with different batteries or charge high enough to match the longevity.

It’s the price of innovation and durability that ultimately gets calculated into the profit margin.

Lack of Competition

No one likes to purchase generic batteries for their smart TV remote, yet sometimes it’s necessary to spend $5 on a 20-pack of no-name, AA batteries than it is to spend $21.75 on a 4-pack of Energizer lithium.

Of course, when it comes to power tools—devices of which we depend on for our home repairs, vehicle repairs, or our very livelihoods—do we really want to depend on a generic brand, 20v battery?

Since there is no universal, name-brand competition amongst batteries in power tools, there’s very little incentive to reduce the prices. Competition, after all, reduces prices as a natural order of events.

For instance, if you have a DeWalt Power drill and it requires a 20v battery, your options are buying a DeWalt 20v battery or something off of Amazon whose description is in mangle English by a brand that’s very difficult to pronounce.

Keep in mind, these batteries are supposed to last for three years. Do you expect to get maximum service life out of the Dollar General brand AA batteries as you expect from Duracell AAs?

The answer is almost assuredly, no and since DeWalt only has to compete with no-name brands, most consumers are going to fork over the extra money to purchase a battery from a reliable business. Worse yet, DeWalt knows that and charges accordingly.

Battery Manufacturing is a High-Tech Process

Battery manufacturing, especially when it comes to lithium batteries, is a high-tech and expensive process. Unfortunately, that means higher prices for the consumer until it reaches a point where production is more streamlined and components are cheaper.

There are three main stages in the process of manufacturing lithium-ion batteries—and other, premium batteries as well:

- Electrode preparation

- Assembling the cells

- Electrochemistry activation

The chemical process that goes into creating the cathode and the anode is extensive and it’s all mixed in before being set aside to dry. The solvents that are used in the cathode mixture are highly-regulated and regulations are costly on a business.

There’s a ton more that goes into the manufacturing of a battery and we could go on and on about it, however, the point of even mentioning the manufacturing process is the cost and a major reason for the excessive expense when it comes to power tool batteries.

Yearly costs, according to Nelson 2019:

- Slurry Mixing: $7,300,000

- Coating/Drying: $13,984,000

- Solvent Recovery: $4,296,000

- Calendering: $4,849,000

- Slitting: $2,891,000

- Vacuum Drying: $2,990,000

- Stacking: $8,086,000

- Welding: $6,864,000

- Enclosing: $11,636,000

- Formation and Aging: $30,482,750

All Things Considered

When it comes to batteries that are associated with power tools, there are a lot of factors that are keeping prices high. Until there are improvements in design and manufacturing, reduced material costs, universal applications for power tool batteries, and more competition, the prices are likely to stay that way.